China's first casing billet hot saw machine is born

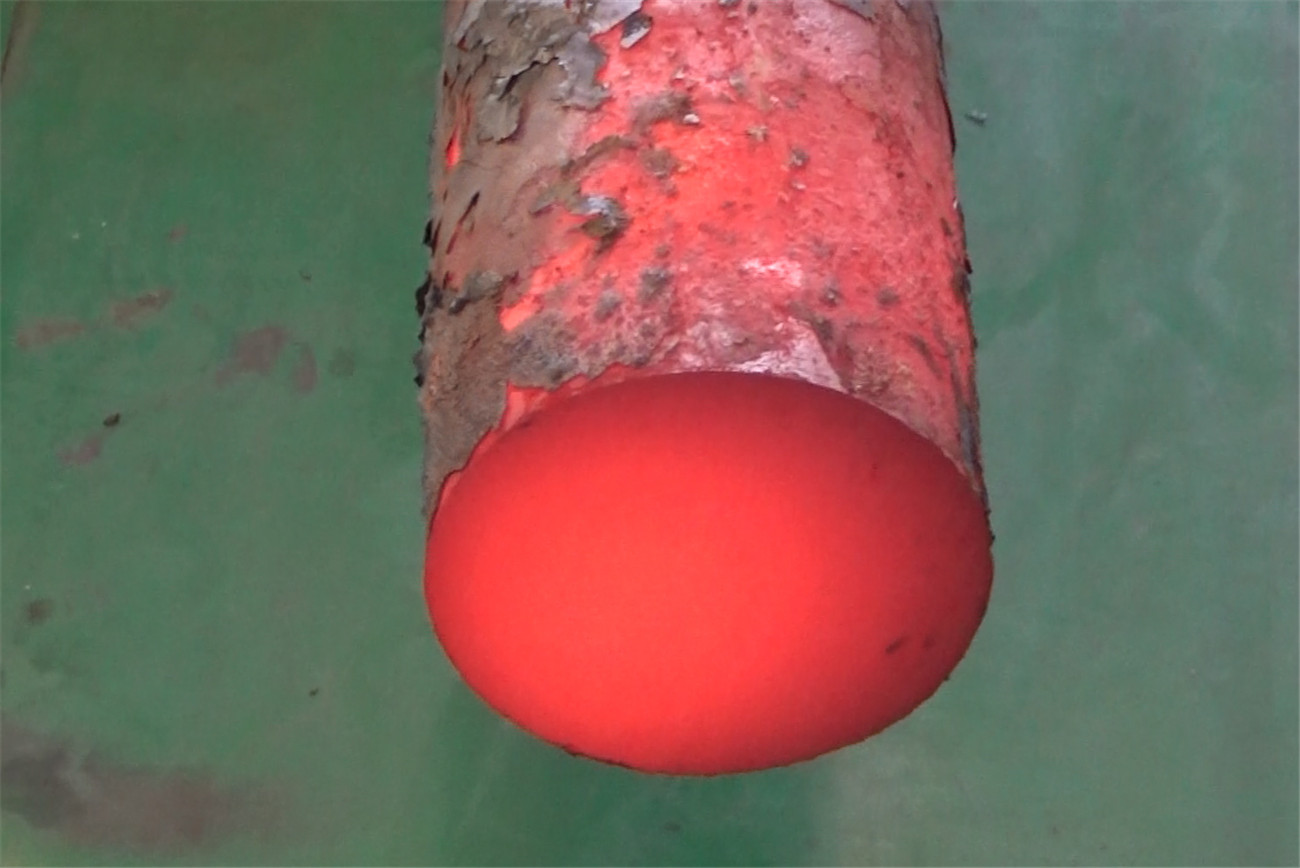

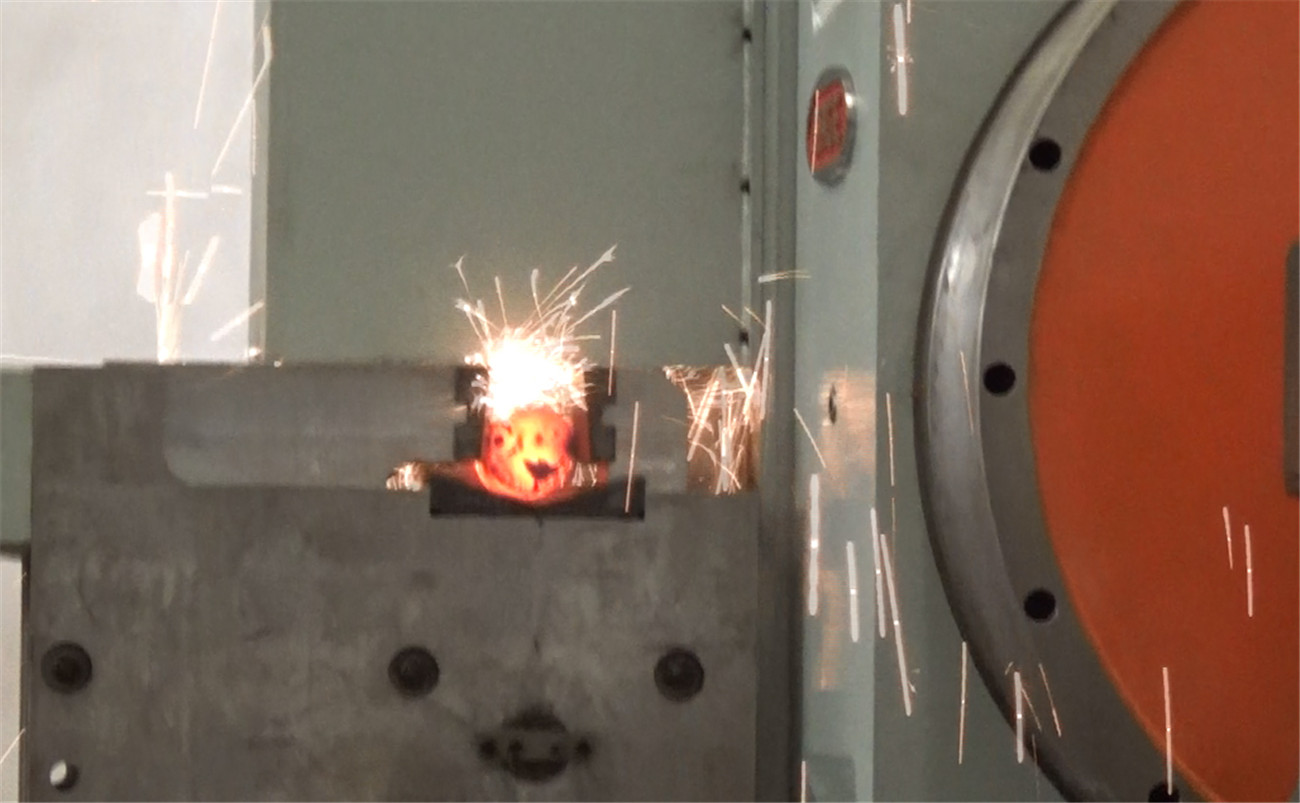

The Chinese Navy has moved from "nearshore" to "deep blue", and Dalian Sangao has moved from "seamless" to "seamless". On May 13, 2018, China's second aircraft carrier departed from the dock of Dalian Shipyard. On the same day, Dalian Sangao Company's Φ 159A six rack continuous rolling pipe unit pipe blank hot saw machine successfully completed a test run, and another first set of equipment was born in Sangao Company; This technology adopts a continuous loop rotation cutting method to quickly cut hot state (1100 ℃~1300 ℃) pipe blanks with fixed length sawing, completely solving the problems of difficult cutting, slow speed, and large fixed length errors of seamless steel pipe blanks. It is a new breakthrough in seamless pipe hot sawing cutting in China, and also opens up a new path for enterprises.

Dalian Sangao Company is engaged in the design and manufacturing of advanced equipment, with its main products including high-frequency pipe making units, stainless steel and titanium alloy pipe making units, cold-formed steel units, etc. The company has developed various forming methods with independent intellectual property rights, including the Sangao forming method, air bending forming method, and multiple Chinese first equipment such as steel pipe milling and sawing machines, steel pipe row sawing machines, strip steel milling machines, laser welding stainless steel pipes, etc.

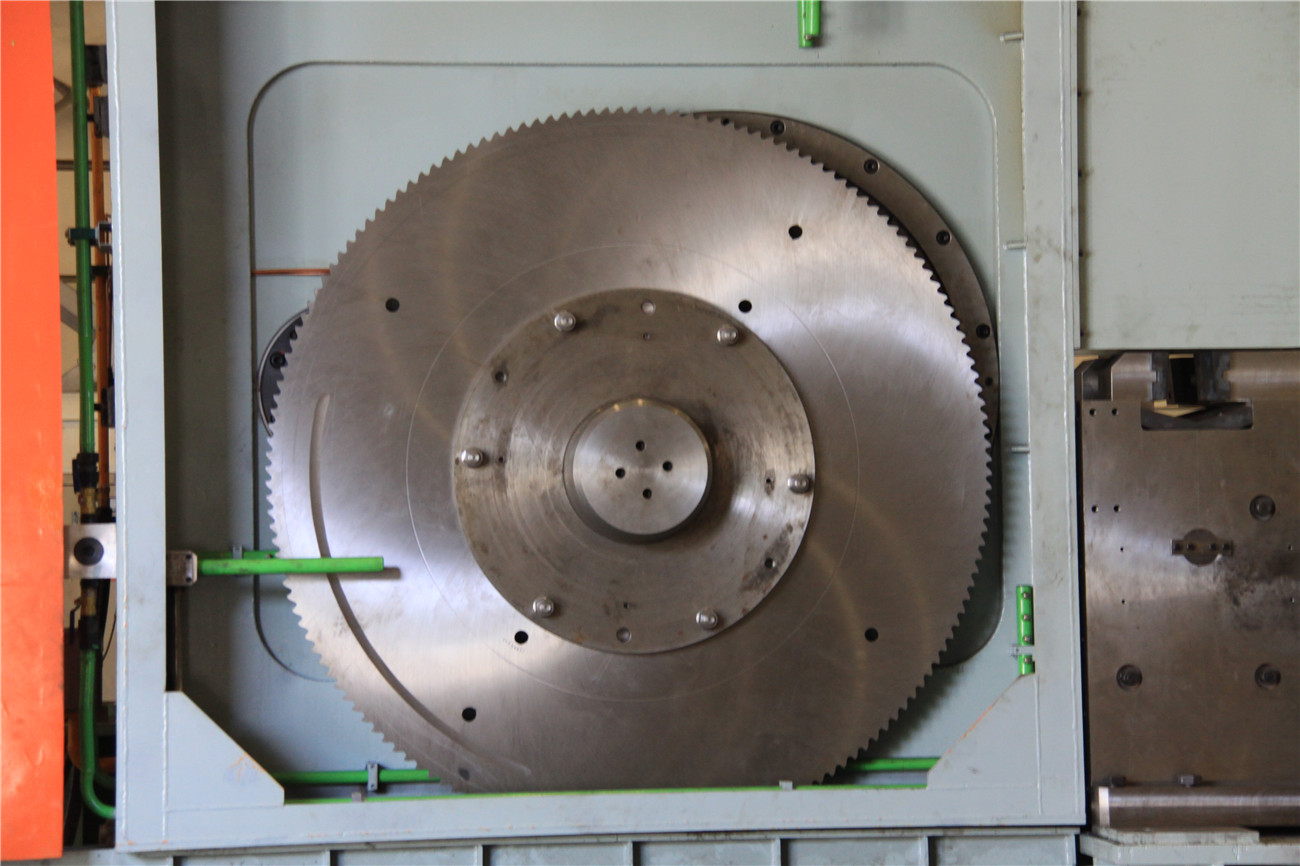

The pipe blank hot saw machine designed and manufactured by the Three Highs Company for Shandong Panjin Steel Pipe adopts a large flywheel energy storage method to complete the cutting of long pipe blanks at temperatures up to 1100 ℃~1300 ℃ with energy-saving, fast, and accurate characteristics. This technology is a revolution in the production process of seamless steel pipes in China, and has made the quality of seamless steel pipe products in China reach the international advanced level.

This technology can be widely applied in the domestic pipe manufacturing industry and has good export prospects, greatly enhancing the discourse power of China's equipment manufacturing industry in the pipe manufacturing field and adding another wonderful flower to China's national industry.